In Part 1 of this series, we explored what a sustainable supply chain is and why it’s a transformational business opportunity. From reducing environmental impact to building brand trust and driving long-term profitability, sustainability is no longer a choice – it is a strategic necessity. But understanding the why is only the first step. Now it’s time to address the how and when.

At a Glance:

- When a business or its leaders do not prioritise sustainability in their supply chain, several negative consequences can arise, impacting the business, its stakeholders, and the environment, as discussed in Part 1.

- Supply chains can account for up to 90% of a company’s total greenhouse gas emissions, according to a 2022 CDP report.

- Leaders can avoid such financial loss and ensure their supply chains are resilient by recognising the signals and knowing when to embed sustainability factors in their supply chain.

Sustainable supply chains aim to minimise carbon footprints, reduce waste, and conserve resources throughout the product lifecycle, from sourcing raw materials to disposal. The urgency is clear: according to a 2022 CDP report, supply chains can account for up to 90% of a company’s total greenhouse gas emissions. For business leaders, the question is no longer whether to prioritise sustainability but when and how to implement meaningful changes without sacrificing operational efficiency.

Manufacturing, retail, and materials sectors carry a carbon liability exceeding US$335 billion from upstream emissions alone. Investors are taking note, with major institutional investors increasingly demanding robust environmental, social, and governance (ESG) commitments and detailed emissions reduction planas conditions for investment.

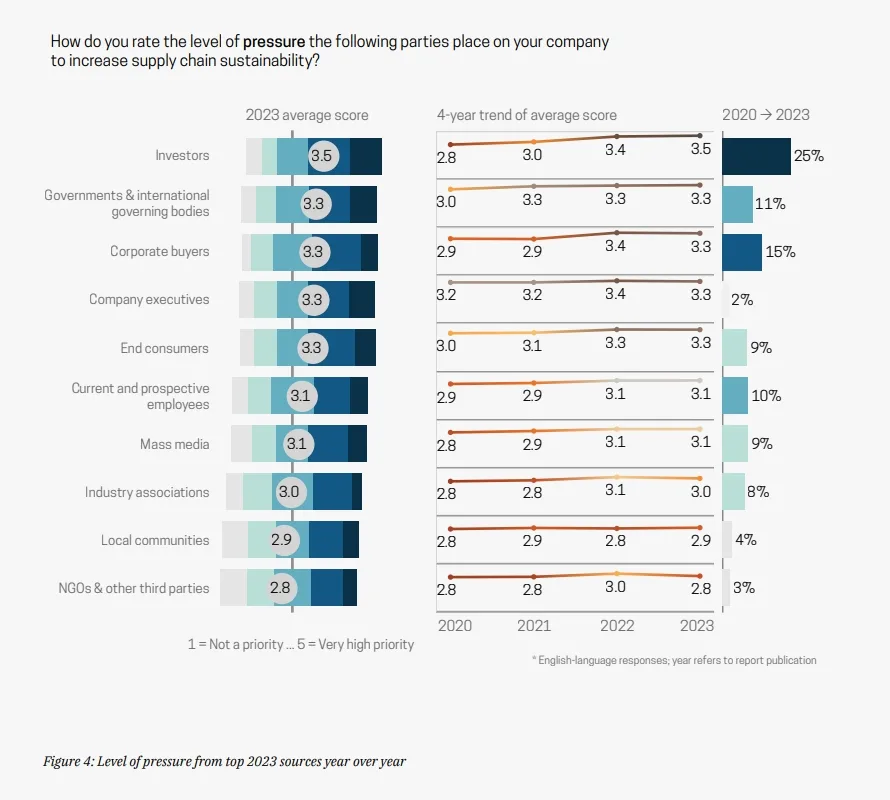

Figure 1 refers to the rate of pressure by different parties, based on a 2024 study by MIT.

According to this study, investors are the fastest-growing source of pressure on companies to enhance supply chain sustainability, with a 25% increase in pressure scores over the study period.

For CEOs and business leaders, these figures and the growing investor scrutiny present both a compelling case for action. The critical challenge now lies in identifying when and how to execute sustainability practices in their supply chains while maintaining competitive advantage.

Knowing it’s time to prioritise sustainability in your supply chain

Now is the time to have sustainability drive your supply chain. A confluence of factors, include:

Increasing consumer demand:

According to this study from Harvard Business Review, Gen Z and Millennials prioritise “humanity” and “transparency” in brands, leading to a 15% and 30% higher likelihood of increased spending, respectively, compared to older generations. With younger generations poised to inherit a significant portion of global wealth (up to $68 trillion by 2030), their preferences will heavily influence market trends.

Desire to mitigate risks:

Global events like the COVID-19 pandemic and the war in Ukraine have highlighted the vulnerability of supply chains to disruptions. Building more sustainable and resilient supply chains helps companies mitigate these risks and ensure business continuity that involves:

- diversifying sourcing,

- assessing geopolitical risks, and

- strengthening relationships with suppliers to enhance adaptability and responsiveness to unexpected challenges.

Commitment to ethical business practices:

Many businesses are recognising the ethical imperative to address issues like child labour, forced labour, and human rights violations within their supply chains. This involves:

- Establishing a code of conduct that outlines the company’s expectations regarding human rights, labour practices, and environmental responsibility,

- Conducting thorough audits and implement unannounced audits,

- Collaborating with stakeholders including NGOs, trade unions, and local communities, can provide valuable insights into potential risks and help develop effective solutions.

Increasingly stringent regulations and reporting on supply chain sustainability:

Regulations establish minimum standards for environmental and social performance, ensuring fair competition and preventing companies from gaining an advantage by exploiting unsustainable practices.

- Unilever’s Supplier Climate Programme is a strategic initiative aimed at significantly reducing greenhouse gas (GHG) emissions across its supply chain, particularly focusing on its key suppliers.

- The programme includes mechanisms for ongoing monitoring of supplier performance regarding emissions reduction efforts. Suppliers are expected to report progress regularly, enabling Unilever to assess compliance and effectiveness in achieving climate goals.

When existing practices are no longer fit for purpose:

Traditional supply chain models and processes don’t adequately address sustainability concerns. A focus on shareholder value is insufficient; a shift to stakeholder value is required. This involves integrating sustainability principles into the business model.

How to Create a Sustainable Supply Chain

Building a sustainable supply chain requires a multi-faceted approach that includes:

- Setting clear sustainability standards: Define sustainability requirements for suppliers and products, including environmental impact, labour standards and ethical sourcing, then incorporate them into supplier selection, contracts and performance evaluations.

- Understanding the entire supply chain: Mapping the entire supply chain to identify potential risks and opportunities for improvement. With this, companies can identify ESG vulnerabilities within their supply chains.

- Engaging with multiple stakeholders: Each stakeholder of the supply chain must understand new expectations, timelines and monitoring. Feedback and concerns must be addressed.

- Obtaining certifications and conducting regular audits: Supplier audits, especially of lower tiers, ensure ESG compliance. Audits assess areas like child and forced labour, safety and fair wages. Third-party certifications from organisations such as the Forest Stewardship Council (FSC) and Fairtrade International verify sustainable practices, helping identify trustworthy suppliers.

- Utilising technology: Leveraging technology, such as blockchain and AI, to improve transparency, traceability, and data analysis.

RenoirESG leads the way in sustainable supply chains, recognising its crucial role in environmental and social risks. We assess risks, embed sustainability into procurement, engage suppliers, and establish policies, structures, and procedures. This integrates sustainability into supply chains, reducing risk, satisfying customers, and saving money.